CHIMNEYS AND VENTS

-

SECTION 501 (IFGC)

GENERAL501.1 Scope.

This chapter shall govern the installation, maintenance, repair and approval of factory-built chimneys, chimney liners, vents and connectors and the utilization of masonry chimneys serving gas-fired appliances. The requirements for the installation, maintenance, repair and approval of factory-built chimneys, chimney liners, vents and connectors serving appliances burning fuels other than fuel gas shall be regulated by the International Mechanical Code. The construction, repair, maintenance and approval of masonry chimneys shall be regulated by the International Building Code.501.2 General.

Every appliance shall discharge the products of combustion to the outdoors, except for appliances exempted by Section 501.8.501.3 Masonry chimneys.

Masonry chimneys shall be constructed in accordance with Section 503.5.3 and the International Building Code.501.4 Minimum size of chimney or vent.

Chimneys and vents shall be sized in accordance with Sections 503 and 504.501.5 Abandoned inlet openings.

Abandoned inlet openings in chimneys and vents shall be closed by an approved method.501.6 Positive pressure.

Where an appliance equipped with a mechanical forced draft system creates a positive pressure in the venting system, the venting system shall be designed for positive pressure applications.501.7 Connection to fireplace.

Connection of any appliance to chimney flues serving fireplaces is prohibited. Refer to IFGC Section 602 for Decorative Appliances for installation in Fireplaces and IFGC Section 603 for Log Lighters.501.7.1 Closure and access.

(Deleted).Deleted

501.7.2 Connection to factory-built fireplace flue.

(Deleted).Deleted

501.7.3 Connection to masonry fireplace flue.

(Deleted).Deleted

501.8 Appliances not required to be vented.

The following appliances shall not be required to be vented.1. Ranges.

2. Built-in domestic cooking units listed and marked for optional venting.

3. Hot plates and laundry stoves.

4. Type 1 clothes dryers (Type 1 clothes dryers shall be exhausted in accordance with the requirements of IFGC Sections 613 and 614).

5. A single booster-type automatic instantaneous water heater, where designed and used solely for the sanitizing rinse requirements of a dishwashing machine, provided that the heater is installed in a commercial kitchen having a mechanical exhaust system. Where installed in this manner, the draft hood, if required, shall be in place and unaltered and the draft hood outlet shall be not less than 36 inches (914 mm) vertically and 6 inches (152 mm) horizontally from any surface other than the heater.

6. Refrigerators.

7. Counter appliances.

8. Direct-fired make-up air heaters.

9. Specialized equipment of limited input such as laboratory burners and gas lights.

Automatically operated equipment vented with a hood or exhaust system shall comply with IFGC Section 503.3.4. Where the appliances and equipment listed in Items 5 to 9 are installed so that the aggregate input rating exceeds 20 Btu/hr per cubic foot (207 watts per m3) of volume of the room or space in which such appliances and equipment are installed, one or more shall be provided with venting systems or other approved means for conveying the vent gases to the outdoor atmosphere so that the aggregate input rating of the remaining unvented appliances and equipment does not exceed the 20 Btu/hr per cubic foot (207 watts per m3) figure. Where the room or space in which the equipment or appliance is installed is directly connected to another room or space by a doorway, archway, or other opening of comparable size that cannot be closed, the volume of such adjacent room or space shall be permitted to be included in the calculations.

501.9 Chimney entrance.

Connectors shall connect to a masonry chimney flue at a point not less than 12 inches (305 mm) above the lowest portion of the interior of the chimney flue.501.10 Connections to exhauster.

Appliance connections to a chimney or vent equipped with a power exhauster shall be made on the inlet side of the exhauster. Joints on the positive pressure side of the exhauster shall be sealed to prevent flue-gas leakage as specified by the manufacturer’s installation instructions for the exhauster.501.11 Masonry chimneys.

Masonry chimneys utilized to vent appliances shall be located, constructed and sized as specified in the manufacturer’s installation instructions for the appliances being vented an d Section 503.501.12 Residential and low-heat appliances flue lining systems.

An approved metallic liner shall be installed in masonry chimneys used to vent gas appliances. The liner shall comply with one of the following:1. Aluminum (1100 or 3003 alloy or equivalent) not less than 0.032 inches thick to 8 inches diameter.

2. Stainless steel (304 or 430 alloy or equivalent) not less than 26 gauge (0.018 inches thick) to 8 inches diameter or not less than 24 gauge (0.024 inches thick) 8 inches diameter and larger.

3. Listed vent systems.

Exception: Metallic liners are not required when each appliance connected into the masonry chimney has a minimum input rating greater than 400,000 Btu/hr.

501.12.1 Terminations.

Metallic liners shall terminate in accordance with the requirements for gas vents in IFGC Section 503.6.6.501.13 Category I appliance flue lining systems.

Flue lining systems for use with Category I appliances shall be limited to the following:1. Flue lining systems complying with Section 501.12.

2. Chimney lining systems listed and labeled for use with gas appliances with draft hoods and other Category I gas appliances listed and labeled for use with Type B vents.

501.14 Category II, III and IV appliance venting systems.

The design, sizing and installation of vents for Category II, III and IV appliances shall be in accordance with the appliance manufacturer’s installation instructions.501.15 Existing chimneys and vents.

Where an appliance is permanently disconnected from an existing chimney or vent, or where an appliance is connected to an existing chimney or vent during the process of a new installation, the chimney or vent shall comply with Sections 501.15.1 through 501.15.4.501.15.1 Size.

The chimney or vent shall be resized as necessary to control flue gas condensation in the interior of the chimney or vent and to provide the appliance or appliances served with the required draft. For Category I appliances, the resizing shall be in accordance with Section 502.501.15.2 Flue passageways.

The flue gas passageway shall be free of obstructions and combustible deposits and shall be cleaned if previously used for venting a solid or liquid fuel-burning appliance or fireplace. The flue liner, chimney inner wall or vent inner wall shall be continuous and shall be free of cracks, gaps, perforations or other damage or deterioration which would allow the escape of combustion products, including gases, moisture and creosote.501.15.3 Cleanout.

Masonry chimney flues shall be provided with a cleanout opening having a minimum height of 6 inches (152 mm). The upper edge of the opening shall be located not less than 6 inches (152 mm) below the lowest chimney inlet opening. The cleanout shall be provided with a tight-fitting, noncombustible cover.501.15.4 Clearances.

Chimneys and vents shall have airspace clearance to combustibles in accordance with the International Building Code and the chimney or vent manufacturer’s installation instructions.Exception: Masonry chimneys without the required airspace clearances shall be permitted to be used if lined or relined with a chimney lining system listed for use in chimneys with reduced clearances in accordance with UL 1777. The chimney clearance shall be not less than permitted by the terms of the chimney liner listing and the manufacturer’s instructions.

501.15.4.1 Fireblocking.

Noncombustible fireblocking shall be provided in accordance with the International Building Code.SECTION 502 (IFGC)

VENTS502.1 General.

All vents, except as provided in Section 503.7, shall be listed and labeled. Type B and BW vents shall be tested in accordance with UL 441. Type L vents shall be tested in accordance with UL 641. Vents for Category II and III appliances shall be tested in accordance with UL 1738. Plastic vents for Category IV appliances shall not be required to be listed and labeledwhere such vents are as specified by the appliance manufacturer and are installed in accordance with the appliance manufacturer’s installation instructions.502.2 Connectors required.

Connectors shall be used to connect appliances to the vertical chimney or vent, except where the chimney or vent is attached directly to the appliance. Vent connector size, material, construction and installation shall be in accordance with Section 503.502.3 Vent application.

The application of vents shall be in accordance with Table 503.4.502.4 Insulation shield.

Where vents pass through insulated assemblies, an insulation shield constructed of steel having a minimum thickness of 0.0187 inch (0.4712 mm) (No. 26 gage) shall be installed to provide clearance between the vent and the insulation material. The clearance shall not be less than the clearance to combustibles specified by the vent manufacturer’s installation instructions. Where vents pass through attic space, the shield shall terminate not less than 2 inches (51 mm) above the insulation materials and shall be secured in place to prevent displacement. Insulation shields provided as part of a listed vent system shall be installed in accordance with the manufacturer’s installation instructions.502.5 Installation.

Vent systems shall be sized, installed and terminated in accordance with the vent and appliance manufacturer’s installation instructions and Section 503.502.6 Support of vents.

All portions of vents shall be adequately supported for the design and weight of the materials employed.502.7 Protection against physical damage.

In concealed locations, where a vent is installed through holes or notches in studs, joists, rafters or similar members less than 11/2 inches (38 mm) from the nearest edge of the member, the vent shall be protected by shield plates. Protective steel shield plates having a minimum thickness of 0.0575 inch (1.463 mm) (No. 16 gage) shall cover the area of the vent where the member is notched or bored and shall extend a minimum of 4 inches (102 mm) above sole plates, below top plates and to each side of a stud, joist or rafter.SECTION 503 (IFGS)

VENTING OF APPLIANCES503.1 General.

The venting of appliances shall be in accordance with Sections 503.2 through 503.16.Deleted

503.2 Venting systems required.

Except as permitted in Sections 503.2.1 through 503.2.4 and 501.8, all appliances shall be connected to venting systems.503.2.1 Ventilating hoods.

Ventilating hoods and exhaust systems shall be permitted to be used to vent appliances installed in commercial applications and to vent industrial appliances, such as where the process itself requires fume disposal.503.2.2 Well-ventilated spaces.

Deleted.Deleted

503.2.3 Direct-vent appliances.

Listed direct-vent appliances shall be installed in accordance with the manufacturer’s instructions and Section 503.8, Item 3.503.2.4 Appliances with integral vents.

Appliances incorporating integral venting means shall be installed in accordance with the manufacturer’s instructions and Section 503.8, Items 1 and 2.503.2.5 Incinerators.

Commercial-industrial-type incinerators shall be vented in accordance with NFPA 82.503.3 Design and construction.

Venting systems shall be designed and constructed so as to convey all flue and vent gases to the outdoors.503.3.1 Appliance draft requirements.

A venting system shall satisfy the draft requirements of the appliance in accordance with the manufacturer’s instructions.503.3.2 Design and construction.

Appliances required to be vented shall be connected to a venting system designed and installed in accordance with the provisions of Sections 503.4 through 503.16.503.3.3 Mechanical draft systems.

Mechanical draft systems shall comply with the following:1. Mechanical draft systems shall be listed and shall be installed in accordance with the manufacturer’s installation instructions for both the appliance and the mechanical draft system.

2. Appliances requiring venting shall be permitted to be vented by means of mechanical draft systems of either forced or induced draft design.

3. Forced draft systems and all portions of induced draft systems under positive pressure during operation shall be designed and installed so as to prevent leakage of flue or vent gases into a building.

4. Vent connectors serving appliances vented by natural draft shall not be connected into any portion of mechanical draft systems operating under positive pressure.

5. Where a mechanical draft system is employed, provisions shall be made to prevent the flow of gas to the main burners when the draft system is not performing so as to satisfy the operating requirements of the appliance for safe performance.

6. The exit terminals of mechanical draft systems shall be not less than 7 feet (2134 mm) above finished ground level where located adjacent to public walkways and shall be located as specified in Section 503.8, Items 1 and 2.

503.3.4 Ventilating hoods and exhaust systems.

Ventilating hoods and exhaust systems shall be permitted to be used to vent appliances installed in commercial applications. Where automatically operated appliances, other than commercial cooking appliances, are vented through a ventilating hood or exhaust system equipped with a damper or with a power means of exhaust, provisions shall be made to allow the flow of gas to the main burners only when the damper is open to a position to properly vent the appliance and when the power means of exhaust is in operation.503.3.5 Air ducts and furnace plenums.

Venting systems shall not extend into or pass through any fabricated air duct or furnace plenum.503.3.6 Above-ceiling air-handling spaces.

Where a venting system passes through an above-ceiling air-handling space or other nonducted portion of an air-handling system, the venting system shall conform to one of the following requirements:1. The venting system shall be a listed special gas vent; other venting system serving a Category III or Category IV appliance; or other positive pressure vent, with joints sealed in accordance with the appliance or vent manufacturer’s instructions.

2. The venting system shall be installed such that fittings and joints between sections are not installed in the above-ceiling space.

3. The venting system shall be installed in a conduit or enclosure with sealed joints separating the interior of the conduit or enclosure from the ceiling space.

503.4 Type of venting system to be used.

The type of venting system to be used shall be in accordance with Table 503.4.TABLE 503.4

TYPE OF VENTING SYSTEM TO BE USEDAPPLIANCES TYPE OF VENTING SYSTEM Listed Category I appliances

Listed appliances equipped with draft hood

Appliances listed for use with Type B gas ventType B gas vent (Section 503.6)

Chimney (Section 503.5)

Single-wall metal pipe (Section 503.7)

Listed chimney lining system for gas venting (Section 503.5.3)

Special gas vent listed for these appliances (Section 503.4.2)Listed vented wall furnaces Type B-W gas vent (Sections 503.6, 608) Category II appliances As specified or furnished by manufacturers of listed appliances

(Sections 503.4.1, 503.4.2)Category III appliances As specified or furnished by manufacturers of listed appliances

(Sections 503.4.1, 503.4.2)Category IV appliances As specified or furnished by manufacturers of listed appliances

(Sections 503.4.1, 503.4.2)Incinerators In accordance with NFPA 82 Deleted Appliances that can be converted for use with solid fuel Chimney (Section 503.5) Unlisted combination gas and oil-burning appliances Chimney (Section 503.5) Listed combination gas and oil-burning appliances Type L vent (Section 503.6) or chimney (Section 503.5) Combination gas and solid fuel-burning appliances Chimney (Section 503.5) Appliances listed for use with chimneys only Chimney (Section 503.5) Unlisted appliances Chimney (Section 503.5) Decorative appliances in vented fireplaces Chimney Gas-fired toilets Single-wall metal pipe (Section 626) Direct-vent appliances See Section 503.2.3 Appliances with integral vent See Section 503.2.4 503.4.1 Plastic piping.

Plastic piping used for venting appliances listed for use with such venting materials shall be approved.503.4.1.1 Plastic vent joints.

Plastic pipe and fittings used to vent appliances shall be installed in accordance with the appliance manufacturer’s installation instructions. Where a primer is required, it shall be of a contrasting color.503.4.2 Special gas vent.

Special gas vent shall be listed and installed in accordance with the special gas vent manufacturer’s installation instructions.503.5 Masonry, metal and factory-built chimneys.

Masonry, metal and factory-built chimneys shall comply with Sections 503.5.1 through 503.5.10.503.5.1 Factory-built chimneys.

Factory-built chimneys shall be installed in accordance with the manufacturer’s installation instructions. Factory-built chimneys used to vent appliances that operate at a positive vent pressure shall be listed for such application.503.5.2 Metal chimneys.

Metal chimneys shall be built and installed in accordance with NFPA 211.503.5.3 Masonry chimneys.

Masonry chimneys shall be built and installed in accordance with NFPA 211 and shall be lined with approved clay flue lining, a listed chimney lining system or other approved material that will resist corrosion, erosion, softening or cracking from vent gases at temperatures up to 1,800°F (982°C).Exception: Masonry chimney flues serving listed gas appliances with draft hoods, Category I appliances and other gas appliances listed for use with Type B vents shall be permitted to be lined with a chimney lining system specifically listed for use only with such appliances. The liner shall be installed in accordance with the liner manufacturer’s installation instructions. A permanent identifying label shall be attached at the point where the connection is to be made to the liner. The label shall read: “This chimney liner is for appliances that burn gas only. Do not connect to solid or liquid fuel-burning appliances or incinerators.”

For installation of gas vents in existing masonry chimneys, see Section 503.6.3.

503.5.4 Chimney termination.

Chimneys for residential-type or low-heat appliances shall extend at least 3 feet (914 mm) above the highest point where they pass through a roof of a building and at least 2 feet (610 mm) higher than any portion of a building within a horizontal distance of 10 feet (3048 mm). Chimneys for medium-heat appliances shall extend at least 10 feet (3048 mm) higher than any portion of any building within 25 feet (7620 mm). Chimneys shall extend at least 5 feet (1524 mm) above the highest connected appliance draft hood outlet or flue collar. Decorative shrouds shall not be installed at the termination of factory-built chimneys except where such shrouds are listed and labeled for use with the specific factory-built chimney system and are installed in accordance with the manufacturer’s installation instructions.Deleted

503.5.5 Size of chimneys.

The effective area of a chimney venting system serving listed appliances with draft hoods, Category I appliances, and other appliances listed for use with Type B vents shall be in accordance with IFGC Section 504 or other approved engineering methods.Exceptions:

1. As an alternate method of sizing an individual chimney venting system for a single appliance with a draft hood, the effective areas of the vent connector and chimney flue shall be not less than the area of the appliance flue collar or draft hood outlet, nor greater than four times the draft hood outlet area.

2. As an alternate method for sizing a chimney venting system connected to two appliances with draft hoods, the effective area of the chimney flue shall be not less than the area of the larger draft hood outlet plus 50 percent of the area of the smaller draft hood outlet, nor greater than four times the smallest draft hood outlet area.

Where an incinerator is vented by a chimney serving other gas utilization appliance, the gas input to the incinerator shall not be included in calculating chimney size, provided the chimney flue diameter is not less than 1 inch (25.4 mm) larger in equivalent diameter than the diameter of the incinerator flue outlet.

503.5.6 Inspection of chimneys.

Before replacing an existing appliance or connecting a vent connector to a chimney, the chimney passageway shall be examined to ascertain that it is clear and free of obstructions and it shall be cleaned if previously used for venting solid or liquid fuel-burning appliances or fireplaces.Exception:Existing chimneys shall be lined in accordance with amended IFGC Section 501.12 unless otherwise approved by the building official.

503.5.6.1 Chimney lining.

Chimneys shall be lined in accordance with NFPA 211.Exception: Where an existing chimney complies with Sections 503.5.6 through 503.5.6.3 and its sizing is in accordance with Section 503.5.5, its continued use shall be allowed where the appliance vented by such chimney is replaced by an appliance of similar type, input rating and efficiency.

503.5.6.2 Cleanouts.

Cleanouts shall be examined to determine if they will remain tightly closed when not in use.503.5.6.3 Unsafe chimneys.

Where inspection reveals that an existing chimney is not safe for the intended application, it shall be repaired, rebuilt, lined, relined or replaced with a vent or chimney to conform to NFPA 211 and it shall be suitable for the appliances to be vented.503.5.7 Chimneys serving appliances burning other fuels.

Chimneys serving appliances burning other fuels shall comply with Sections 503.5.7.1 through 503.5.7.4.503.5.7.1 Solid fuel-burning appliances.

An appliance shall not be connected to a chimney flue serving a separate appliance designed to burn solid fuel.503.5.7.2 Liquid fuel-burning appliances.

Where one chimney flue serves gas appliances and liquid fuel-burning appliances, the appliances shall be connected through separate openings or shall be connected through a single opening where joined by a suitable fitting located as close as practical to the chimney. Where two or more openings are provided into one chimney flue, they shall be at different levels. Where the appliances are automatically controlled, they shall be equipped with safety shutoff devices.503.5.7.3 Combination gas and solid fuel-burning appliances.

A combination gas- and solid fuel-burning appliance shall be permitted to be connected to a single chimney flue where equipped with a manual reset device to shut off gas to the main burner in the event of sustained backdraft or flue gas spillage. The chimney flue shall be sized to properly vent the appliance.503.5.7.4 Combination gas- and oil fuel-burning appliances.

A listed combination gas- and oil fuel-burning appliance shall be permitted to be connected to a single chimney flue. The chimney flue shall be sized to properly vent the appliance.503.5.8 Support of chimneys.

All portions of chimneys shall be supported for the design and weight of the materials employed. Factory-built chimneys shall be supported and spaced in accordance with the manufacturer’s installation instructions.503.5.9 Cleanouts.

Where a chimney that formerly carried flue products from liquid or solid fuel-burning appliances is used with an appliance using fuel gas, an accessible cleanout shall be provided. The cleanout shall have a tight-fitting cover and shall be installed so its upper edge is at least 6 inches (152 mm) below the lower edge of the lowest chimney inlet opening.503.5.10 Space surrounding lining or vent.

The remaining space surrounding a chimney liner, gas vent, special gas vent or plastic piping installed within a masonry chimney flue shall not be used to vent another appliance. The insertion of another liner or vent within the chimney as provided in this code and the liner or vent manufacturer’s instructions shall not be prohibited.The remaining space surrounding a chimney liner, gas vent, special gas vent or plastic piping installed within a masonry, metal or factory-built chimney shall not be used to supply combustion air. Such space shall not be prohibited from supplying combustion air to direct-vent appliances designed for installation in a solid fuel-burning fireplace and installed in accordance with the manufacturer’s installation instructions.

503.6 Gas vents.

Gas vents shall comply with Sections 503.6.1 through 503.6.13 (see Section 202, Definitions).503.6.1 Installation, general.

Gas vents shall be installed in accordance with the manufacturer’s installation instructions.503.6.2 Type B-W vent capacity.

A Type B-W gas vent shall have a listed capacity not less than that of the listed vented wall furnace to which it is connected.503.6.3 Gas vents installed within masonry chimneys.

Gas vents installed within masonry chimneys shall be installed in accordance with the manufacturer’s installation instructions. Gas vents installed within masonry chimneys shall be identified with a permanent label installed at the point where the vent enters the chimney. The label shall contain the following language: “This gas vent is for appliances that burn gas. Do not connect to solid or liquid fuel-burning appliances or incinerators.”503.6.4 Gas vent terminations.

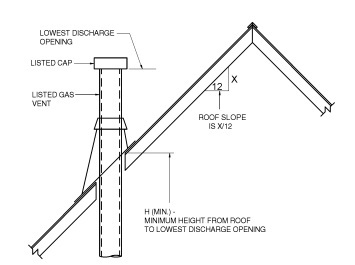

A gas vent shall terminate in accordance with one of the following:1. Gas vents that are 12 inches (305 mm) or less in size and located not less than 8 feet (2438 mm) from a vertical wall or similar obstruction shall terminate above the roof in accordance with Figure 503.6.4.

2. Gas vents that are over 12 inches (305 mm) in size or are located less than 8 feet (2438 mm) from a vertical wall or similar obstruction shall terminate not less than 2 feet (610 mm) above the highest point where they pass through the roof and not less than 2 feet (610 mm) above any portion of a building within 10 feet (3048 mm) horizontally.

3. As provided for industrial appliances in Section 503.2.2.

4. As provided for direct-vent systems in Section 503.2.3.

5. As provided for appliances with integral vents in Section 503.2.4.

6. As provided for mechanical draft systems in Section 503.3.3.

7. As provided for ventilating hoods and exhaust systems in Section 503.3.4.

ROOF SLOPE H (min) ft Flat to 6/12 1.0 Over 6/12 to 7/12 1.25 Over 7/12 to 8/12 1.5 Over 8/12 to 9/12 2.0 Over 9/12 to 10/12 2.5 Over 10/12 to 11/12 3.25 Over 11/12 to 12/12 4.0 Over 12/12 to 14/12 5.0 Over 14/12 to 16/12 6.0 Over 16/12 to 18/12 7.0 Over 18/12 to 20/12 7.5 Over 20/12 to 21/12 8.0 For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm. FIGURE 503.6.4

TERMINATION LOCATIONS FOR GAS VENTS WITH

LISTED CAPS 12 INCHES OR LESS IN SIZE

AT LEAST 8 FEET FROM A VERTICAL WALL503.6.4.1 Decorative shrouds.

Decorative shrouds shall not be installed at the termination of gas vents except where such shrouds are listed for use with the specific gas venting system and are installed in accordance with manufacturer’s installation instructions.503.6.5 Minimum height.

A Type B or L gas vent shall terminate at least 5 feet (1524 mm) in vertical height above the highest connected appliance draft hood or flue collar. A Type B-W gas vent shall terminate at least 12 feet (3658 mm) in vertical height above the bottom of the wall furnace.503.6.6 Roof terminations.

Gas vents shall extend through the roof flashing, roof jack or roof thimble and terminate with a listed cap or listed roof assembly.503.6.7 Forced air inlets.

Gas vents shall terminate not less than 3 feet (914 mm) above any forced air inlet located within 10 feet (3048 mm).503.6.8 Exterior wall penetrations.

A gas vent extending through an exterior wall shall not terminate adjacent to the wall or below eaves or parapets, except as provided in Sections 503.2.3 and 503.3.3.503.6.9 Size of gas vents.

Venting systems shall be sized and constructed in accordance with Section 504 or other approved engineering methods and the gas vent and appliance manufacturer’s installation instructions.503.6.9.1 Category I appliances.

The sizing of natural draft venting systems serving one or more listed appliances equipped with a draft hood or appliances listed for use with Type B gas vent, installed in a single story of a building, shall be in accordance with one of the following methods:1. The provisions of Section 504.

2. For sizing an individual gas vent for a single draft-hood-equipped appliance, the effective area of the vent connector and the gas vent shall be not less than the area of the appliance draft hood outlet, nor greater than four times the draft hood outlet area.

3. For sizing a gas vent connected to two appliances with draft hoods, the effective area of the vent shall be not less than the area of the larger draft hood outlet plus 50 percent of the area of the smaller draft hood outlet, nor greater than four times the smaller draft hood outlet area.

4. Approved engineering practices.

503.6.9.2 Vent offsets.

Type B and L vents sized in accordance with Item 2 or 3 of Section 503.6.9.1 shall extend in a generally vertical direction with offsets not exceeding 45 degrees (0.79 rad), except that a vent system having not more than one 60-degree (1.04 rad) offset shall be permitted. Any angle greater than 45 degrees (0.79 rad) from the vertical is considered horizontal. The total horizontal distance of a vent plus the horizontal vent connector serving draft hood-equipped appliances shall be not greater than 75 percent of the vertical height of the vent.503.6.9.3 Category II, III and IV appliances.

The sizing of gas vents for Category II, III and IV appliances shall be in accordance with the appliance manufacturer’s instructions.503.6.9.4 Mechanical draft.

Chimney venting systems using mechanical draft shall be sized in accordance with approved engineering methods.503.6.10 Gas vents serving appliances on more than one floor.

A common vent shall be permitted in multistory installations to vent Category I appliances located on more than one floor level, provided that the venting system is designed and installed in accordance with approved engineering methods. For the purpose of this section, crawl spaces, basements and attics shall be considered as floor levels.503.6.10.1 Appliance separation.

All appliances connected to the common vent shall be located in rooms separated from occupiable space. Each of these rooms shall have provisions for an adequate supply of combustion, ventilation and dilution air that is not supplied from an occupiable space.Deleted

503.6.10.2 Sizing.

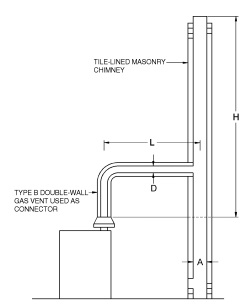

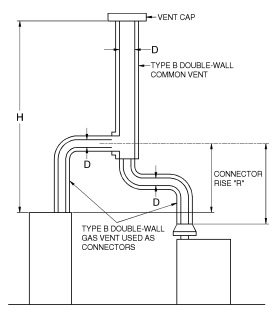

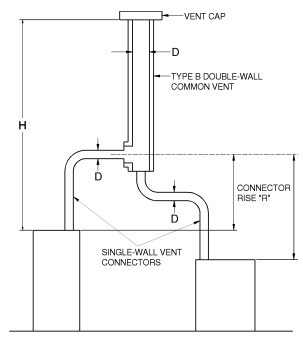

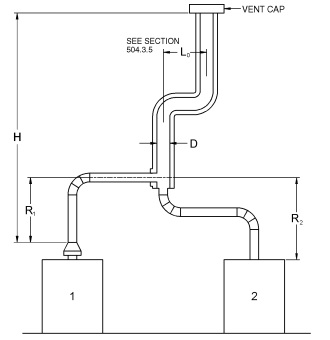

The size of the connectors and common segments of multistory venting systems for appliances listed for use with Type B double-wall gas vents shall be in accordance with Table 504.3(1), provided that:1. The available total height (H) for each segment of a multistory venting system is the vertical distance between the level of the highest draft hood outlet or flue collar on that floor and the centerline of the next highest interconnection tee.

2. The size of the connector for a segment is determined from the appliance input rating and available connector rise, and shall not be smaller than the draft hood outlet or flue collar size.

3. The size of the common vertical segment, and of the interconnection tee at the base of that segment, shall be based on the total appliance input rating entering that segment and its available total height.

503.6.11 Support of gas vents.

Gas vents shall be supported and spaced in accordance with the manufacturer’s installation instructions.503.6.12 Marking.

In those localities where solid and liquid fuels are used extensively, gas vents shall be permanently identified by a label attached to the wall or ceiling at a point where the vent connector enters the gas vent. The determination of where such localities exist shall be made by the code official. The label shall read:“This gas vent is for appliances that burn gas. Do not connect to solid or liquid fuel-burning appliances or incinerators.”

503.6.13 Fastener penetrations.

Screws, rivets and other fasteners shall not penetrate the inner wall of double-wall gas vents, except at the transition from an appliance draft hood outlet, a flue collar or a single-wall metal connector to a double-wall vent.503.7 Single-wall metal pipe.

Single-wall metal pipe vents shall comply with Sections 503.7.1 through 503.7.13.503.7.1 Construction.

Single-wall metal pipe shall be constructed of galvanized sheet steel not less than 0.0304 inch (0.7 mm) thick, or other approved, noncombustible, corrosion-resistant material.503.7.2 Cold climate.

Uninsulated single-wall metal pipe shall not be used outdoors for venting appliances in regions where the 99-percent winter design temperature is below 32°F (0°C).503.7.3 Termination.

Single-wall metal pipe shall terminate at least 5 feet (1524 mm) in vertical height above the highest connected appliance draft hood outlet or flue collar. Single-wall metal pipe shall extend at least 2 feet (610 mm) above the highest point where it passes through a roof of a building and at least 2 feet (610 mm) higher than any portion of a building within a horizontal distance of 10 feet (3048 mm). An approved cap or roof assembly shall be attached to the terminus of a single-wall metal pipe.503.7.4 Limitations of use.

Single-wall metal pipe shall be used only for runs directly from the space in which the appliance is located through the roof or exterior wall to the outdoor atmosphere.503.7.5 Roof penetrations.

A pipe passing through a roof shall extend without interruption through the roof flashing, roof jack or roof thimble. Where a single-wall metal pipe passes through a roof constructed of combustible material, a noncombustible, nonventilating thimble shall be used at the point of passage. The thimble shall extend at least 18 inches (457 mm) above and 6 inches (152 mm) below the roof with the annular space open at the bottom and closed only at the top. The thimble shall be sized in accordance with Section 503.7.7.503.7.6 Installation.

Single-wall metal pipe shall not originate in any unoccupied attic or concealed space and shall not pass through any attic, inside wall, concealed space or floor. The installation of a single-wall metal pipe through an exterior combustible wall shall comply with Section 503.7.7.503.7.7 Single-wall penetrations of combustible walls.

A single-wall metal pipe shall not pass through a combustible exterior wall unless guarded at the point of passage by a ventilated metal thimble not smaller than the following:1. For listed appliances with draft hoods and appliances listed for use with Type B gas vents, the thimble shall be not less than 4 inches (102 mm) larger in diameter than the metal pipe. Where there is a run of not less than 6 feet (1829 mm) of metal pipe in the open between the draft hood outlet and the thimble, the thimble shall be permitted to be not less than 2 inches (51 mm) larger in diameter than the metal pipe.

2. For unlisted appliances having draft hoods, the thimble shall be not less than 6 inches (152 mm) larger in diameter than the metal pipe.

3. For residential and low-heat appliances, the thimble shall be not less than 12 inches (305 mm) larger in diameter than the metal pipe.

Exception: In lieu of thimble protection, all combustible material in the wall shall be removed a sufficient distance from the metal pipe to provide the specified clearance from such metal pipe to combustible material. Any material used to close up such opening shall be noncombustible.

503.7.8 Clearances.

Minimum clearances from single-wall metal pipe to combustible material shall be in accordance with Table 503.10.5. The clearance from single-wall metal pipe to combustible materialshall be permitted to be reduced where the combustible material is protected as specified for vent connectors in Table 308.2.503.7.9 Size of single-wall metal pipe.

A venting system constructed of single-wall metal pipe shall be sized in accordance with one of the following methods and the appliance manufacturer’s instructions:1. For a draft hood-equipped appliance, in accordance with IFGC Section 504.

2. For a venting system for a single appliance with a draft hood, the areas of the connector and the pipe each shall be not less than the area of the appliance flue collar or draft hood outlet, whichever is smaller. The vent area shall not be greater than four times the draft hood outlet area.

3. Other approved engineering methods.

503.7.10 Pipe geometry.

Any shaped single-wall metal pipe shall be permitted to be used, provided that its equivalent effective area is equal to the effective area of the round pipe for which it is substituted, and provided that the minimum internal dimension of the pipe is not less than 2 inches (51 mm).503.7.11 Termination capacity.

The vent cap or a roof assembly shall have a venting capacity of not less than that of the pipe to which it is attached.503.7.12 Support of single-wall metal pipe.

All portions of single-wall metal pipe shall be supported for the design and weight of the material employed.503.7.13 Marking.

Single-wall metal pipe shall comply with the marking provisions of Section 503.6.12.503.8 Venting system termination location.

The location of venting system terminations shall comply with the following (see Appendix C):1. A mechanical draft venting system shall terminate at least 3 feet (914 mm) above any forced-air inlet located within 10 feet (3048 mm).

Exceptions:

1. This provision shall not apply to the combustion air intake of a direct-vent appliance.

2. This provision shall not apply to the separation of the integral outdoor air inlet and flue gas discharge of listed outdoor appliances.

2. A mechanical draft venting system, excluding direct-vent appliances, shall terminate at least 4 feet (1219 mm) below, 4 feet (1219 mm) horizontally from, or 1 foot (305 mm) above any door, operable window or gravity air inlet into any building. The bottom of the vent terminal shall be located at least 12 inches (305 mm) above finished ground level.

3. The vent terminal of a direct-vent appliance with an input of 10,000 Btu per hour (3 kW) or less shall be located at least 6 inches (152 mm) from any air opening into a building, and such an appliance with an input over 10,000 Btu per hour (3 kW) but not over 50,000 Btu per hour (14.7 kW) shall be installed with a 9-inch (230 mm) vent termination clearance, and an appliance with an input over 50,000 Btu/h (14.7 kW) shall have at least a 12-inch (305 mm) vent termination clearance. The bottom of the vent terminal and the air intake shall be located at least 12 inches (305 mm) above finished ground level.

4. Through-the-wall vents for Category II and IV appliances and noncategorized condensing appliances shall not terminate over public walkways or over an area where condensate or vapor could create a nuisance or hazard or could be detrimental to the operation of regulators, relief valves or other equipment. Where local experience indicates that condensate is a problem with Category I and III appliances, this provision shall also apply. Drains for condensate shall be installed in accordance with the appliance and vent manufacturers’ instructions.

503.9 Condensation drainage.

Provisions shall be made to collect and dispose of condensate from venting systems serving Category II and IV appliances and noncategorized condensing appliances in accordance with Section 503.8, Item 4. Where local experience indicates that condensation is a problem, provision shall be made to drain off and dispose of condensate from venting systems serving Category I and III appliances in accordance with Section 503.8, Item 4.503.10 Vent connectors for Category I appliances.

Vent connectors for Category I appliances shall comply with Sections 503.10.1 through 503.10.14.503.10.1 Where required.

A vent connector shall be used to connect an appliance to a gas vent, chimney or single-wall metal pipe, except where the gas vent, chimney or single-wall metal pipe is directly connected to the appliance.503.10.2 Materials.

Vent connectors shall be constructed in accordance with Sections 503.10.2.1 through 503.10.2.5.503.10.2.1 General.

A vent connector shall be made of noncombustible corrosion-resistant material capable of withstanding the vent gas temperature produced by the appliance and of sufficient thickness to withstand physical damage.503.10.2.2 Vent connectors located in unconditioned areas.

Where the vent connector used for an appliance having a draft hood or a Category I appliance is located in or passes through attics, crawl spaces or other unconditioned spaces, that portion of the vent connector shall be listed Type B, Type L or listed vent material having equivalent insulation properties.Exception: Single-wall metal pipe located within the exterior walls of the building in areas having a local 99-percent winter design temperature of 5°F (-15°C) or higher shall be permitted to be used in unconditioned spaces other than attics and crawl spaces.

503.10.2.3 Residential-type appliance connectors.

Where vent connectors for residential-type appliances are not installed in attics or other unconditioned spaces, connectors for listed appliances having draft hoods, appliances having draft hoods and equipped with listed conversion burners and Category I appliances shall be one of the following:1. Type B or L vent material;

2. Galvanized sheet steel not less than 0.018 inch (0.46 mm) thick;

3. Aluminum (1100 or 3003 alloy or equivalent) sheet not less than 0.027 inch (0.69 mm) thick;

4. Stainless steel sheet not less than 0.012 inch (0.31 mm) thick;

5. Smooth interior wall metal pipe having resistance to heat and corrosion equal to or greater than that of Item 2, 3 or 4 above; or

6. A listed vent connector.

Vent connectors shall not be covered with insulation.

Exception: Listed insulated vent connectors shall be installed in accordance with the manufacturer’s installation instructions.

503.10.2.4 Low-heat equipment.

A vent connector for a nonresidential, low-heat appliance shall be a factory-built chimney section or steel pipe having resistance to heat and corrosion equivalent to that for the appropriate galvanized pipe as specified in Table 503.10.2.4. Factory-built chimney sections shall be joined together in accordance with the chimney manufacturer’s instructions.TABLE 503.10.2.4

MINIMUM THICKNESS FOR GALVANIZED STEEL VENT CONNECTORS FOR LOW-HEAT APPLIANCESDIAMETER OF CONNECTOR

(inches)MINIMUM THICKNESS

(inch)Less than 6 0.019 6 to less than 10 0.023 10 to 12 inclusive 0.029 14 to 16 inclusive 0.034 Over 16 0.056 For SI: 1 inch = 25.4 mm. 503.10.2.5 Medium-heat appliances.

Vent connectors for medium-heat appliances shall be constructed of factory-built medium-heat chimney sections or steel of a thickness not less than that specified in Table 503.10.2.5 and shall comply with the following:1. A steel vent connector for an appliance with a vent gas temperature in excess of 1,000°F (538°C) measured at the entrance to the connector shall be lined with medium-duty fire brick (ASTM C64, Type F), or the equivalent.

2. The lining shall be at least 21/2 inches (64 mm) thick for a vent connector having a diameter or greatest cross-sectional dimension of 18 inches (457 mm) or less.

3. The lining shall be at least 41/2 inches (114 mm) thick laid on the 41/2-inch (114 mm) bed for a vent connector having a diameter or greatest cross-sectional dimension greater than 18 inches (457 mm).

4. Factory-built chimney sections, if employed, shall be joined together in accordance with the chimney manufacturer’s instructions.

TABLE 503.10.2.5

MINIMUM THICKNESS FOR STEEL VENT

CONNECTORS FOR MEDIUM-HEAT APPLIANCESVENT CONNECTOR SIZE Diameter

(inches)Area

(square inches)MINIMUM THICKNESS

(inch)Up to 14 Up to 154 0.053 Over 14 to 16 154 to 201 0.067 Over 16 to 18 201 to 254 0.093 Over 18 Larger than 254 0.123 For SI: 1 inch = 25.4 mm, 1 square inch = 645.16 mm2. 503.10.3 Size of vent connector.

Vent connectors shall be sized in accordance with Sections 503.10.3.1 through 503.10.3.5.503.10.3.1 Single draft hood and fan-assisted.

A vent connector for an appliance with a single draft hood or for a Category I fan-assisted combustion system appliance shall be sized and installed in accordance with Section 504 or other approved engineering methods.503.10.3.2 Multiple draft hood.

For a single appliance having more than one draft hood outlet or flue collar, the manifold shall be constructed according to the instructions of the appliance manufacturer. Where there are no instructions, the manifold shall be designed and constructed in accordance with approved engineering practices. As an alternate method, the effective area of the manifold shall equal the combined area of the flue collars or draft hood outlets and the vent connectors shall have a minimum 1-foot (305 mm) rise.503.10.3.3 Multiple appliances.

Where two or more appliances are connected to a common vent or chimney, each vent connector shall be sized in accordance with Section 504 or other approved engineering methods.As an alternative method applicable only when all of the appliances are draft hood equipped, each vent connector shall have an effective area not less than the area of the draft hood outlet of the appliance to which it is connected.

503.10.3.4 Common connector/manifold.

Where two or more appliances are vented through a common vent connector or vent manifold, the common vent connector or vent manifold shall be located at the highest level consistent with available headroom and the required clearance to combustible materials and shall be sized in accordance with Section 504 or other approved engineering methods.As an alternate method applicable only where there are two draft hood-equipped appliances, the effective area of the common vent connector or vent manifold and all junction fittings shall be not less than the area of the larger vent connector plus 50 percent of the area of the smaller flue collar outlet.

503.10.3.5 Size increase.

Where the size of a vent connector is increased to overcome installation limitations and obtain connector capacity equal to the appliance input, the size increase shall be made at the appliance draft hood outlet.503.10.4 Two or more appliances connected to a single vent or chimney.

Where two or more vent connectors enter a common vent, chimney flue or single-wall metal pipe, the smaller connector shall enter at the highest level consistent with the available headroom or clearance to combustible material. Vent connectors serving Category I appliances shall not be connected to any portion of a mechanical draft system operating under positive static pressure, such as those serving Category III or IV appliances.503.10.4.1 Two or more openings.

Where two or more openings are provided into one chimney flue or vent, the openings shall be at different levels, or the connectors shall be attached to the vertical portion of the chimney or vent at an angle of 45 degrees (0.79 rad) or less relative to the vertical.503.10.5 Clearance.

Minimum clearances from vent connectors to combustible material shall be in accordance with Table 503.10.5.Exception: The clearance between a vent connector and combustible material shall be permitted to be reduced where the combustible material is protected as specified for vent connectors in Table 308.2.

Deleted

TABLE 503.10.5a

CLEARANCES FOR CONNECTORSAPPLIANCE MINIMUM DISTANCE FROM COMBUSTIBLE MATERIAL Listed Type B gas

vent materialListed Type L vent

materialSingle-wall

metal pipeFactory-built

chimney sectionsListed appliances with draft hoods and appliances listed for use with

Type B gas ventsAs listed As listed 6 inches As listed Residential boilers and furnaces with listed gas conversion burner and

with draft hood6 inches 6 inches 9 inches As listed Residential appliances listed for use with Type L vents Not permitted As listed 9 inches As listed Listed gas-fired toilets Not permitted As listed As listed As listed Unlisted residential appliances with draft hood Not permitted 6 inches 9 inches As listed Residential and low-heat appliances other than above Not permitted 9 inches 18 inches As listed Medium-heat appliances Not permitted Not permitted 36 inches As listed For SI: 1 inch = 25.4 mm. a. These clearances shall apply unless the manufacturer’s installation instructions for a listed appliance or connector specify different clearances, in which case the listed clearances shall apply. 503.10.6 Joints.

Joints between sections of connector piping and connections to flue collars and draft hood outlets shall be fastened by one of the following methods:1. Sheet metal screws.

2. Vent connectors of listed vent material assembled and connected to flue collars or draft hood outlets in accordance with the manufacturers’ instructions.

3. Other approved means.

503.10.7 Slope.

A vent connector shall be installed without dips or sags and shall slope upward toward the vent or chimney at least 1/4 inch per foot (21 mm/m).Exception: Vent connectors attached to a mechanical draft system installed in accordance with the appliance and draft system manufacturers’ instructions.

503.10.8 Length of vent connector.

The maximum horizontal length of a single-wall connector shall be 75 percent of the height of the chimney or vent except for engineered systems. The maximum horizontal length of a Type B double-wall connector shall be 100 percent of the height of the chimney or vent except for engineered systems.503.10.9 Support.

A vent connector shall be supported for the design and weight of the material employed to maintain clearances and prevent physical damage and separation of joints.503.10.10 Chimney connection.

Where entering a flue in a masonry or metal chimney, the vent connector shall be installed above the extreme bottom to avoid stoppage. Where a thimble or slip joint is used to facilitate removal of the connector, the connector shall be firmly attached to or inserted into the thimble or slip joint to prevent the connector from falling out. Means shall be employed to prevent the connector from entering so far as to restrict the space between its end and the opposite wall of the chimney flue (see Section 501.9).503.10.11 Inspection.

The entire length of a vent connector shall be provided with ready access for inspection, cleaning and replacement.503.10.12 Fireplaces.

A vent connector shall not be connected to a chimney flue serving a fireplace unless the fireplace flue opening is permanently sealed.503.10.13 Passage through ceilings, floors or walls.

Single-wall metal pipe connectors shall not pass through any wall, floor or ceiling except as permitted by Section 503.7.4.503.10.14 Medium-heat connectors.

Vent connectors for medium-heat appliances shall not pass through walls or partitions constructed of combustible material.503.11 Vent connectors for Category II, III and IV appliances.

Vent connectors for Category II, III and IV appliances shall be as specified for the venting systems in accordance with Section 503.4.503.12 Draft hoods and draft controls.

The installation of draft hoods and draft controls shall comply with Sections 503.12.1 through 503.12.7.503.12.1 Appliances requiring draft hoods.

Vented appliances shall be installed with draft hoods.Exception: Dual oven-type combination ranges; direct-vent appliances; fan-assisted combustion system appliances; appliances requiring chimney draft for operation; single firebox boilers equipped with conversion burners with inputs greater than 400,000 Btu per hour (117 kW); appliances equipped with blast, power or pressure burners that are not listed for use with draft hoods; and appliances designed for forced venting.

503.12.2 Installation.

A draft hood supplied with or forming a part of a listed vented appliance shall be installed without alteration, exactly as furnished and specified by the appliance manufacturer.503.12.2.1 Draft hood required.

If a draft hood is not supplied by the appliance manufacturer where one is required, a draft hood shall be installed, shall be of a listed or approved type and, in the absence of other instructions, shall be of the same size as the appliance flue collar. Where a draft hood is required with a conversion burner, it shall be of a listed or approved type.503.12.2.2 Special design draft hood.

Where it is determined that a draft hood of special design is needed or preferable for a particular installation, the installation shall be in accordance with the recommendations of the appliance manufacturer and shall be approved.503.12.3 Draft control devices.

Where a draft control device is part of the appliance or is supplied by the appliance manufacturer, it shall be installed in accordance with the manufacturer’s instructions. In the absence of manufacturer’s instructions, the device shall be attached to the flue collar of the appliance or as near to the appliance as practical.503.12.4 Additional devices.

Appliances requiring a controlled chimney draft shall be permitted to be equipped with a listed double-acting barometric-draft regulator installed and adjusted in accordance with the manufacturer’s instructions.503.12.5 Location.

Draft hoods and barometric draft regulators shall be installed in the same room or enclosure as the appliance in such a manner as to prevent any difference in pressure between the hood or regulator and the combustion air supply.503.12.6 Positioning.

Draft hoods and draft regulators shall be installed in the position for which they were designed with reference to the horizontal and vertical planes and shall be located so that the relief opening is not obstructed by any part of the appliance or adjacent construction. The appliance and its draft hood shall be located so that the relief opening is accessible for checking vent operation.503.12.7 Clearance.

A draft hood shall be located so its relief opening is not less than 6 inches (152 mm) from any surface except that of the appliance it serves and the venting system to which the draft hood is connected. Where a greater or lesser clearance is indicated on the appliance label, the clearance shall be not less than that specified on the label. Such clearances shall not be reduced.503.13 Manually operated dampers.

A manually operated damper shall not be placed in the vent connector for any appliance. Fixed baffles shall not be classified as manually operated dampers.503.14 Automatically operated vent dampers.

An automatically operated vent damper shall be of a listed type.503.15 Obstructions.

Devices that retard the flow of vent gases shall not be installed in a vent connector, chimney or vent. The following shall not be considered as obstructions:1. Draft regulators and safety controls specifically listed for installation in venting systems and installed in accordance with the manufacturer’s installation instructions.

2. Approved draft regulators and safety controls that are designed and installed in accordance with approved engineering methods.

3. Listed heat reclaimers and automatically operated vent dampers installed in accordance with the manufacturer’s installation instructions.

4. Approved economizers, heat reclaimers and recuperators installed in venting systems of appliances not required to be equipped with draft hoods, provided that the appliance manufacturer’s instructions cover the installation of such a device in the venting system and performance in accordance with Sections 503.3 and 503.3.1 is obtained.

5. Vent dampers serving listed appliances installed in accordance with Sections 504.2.1 and 504.3.1 or other approved engineering methods.

503.16 Outside wall penetrations.

Where vents, including those for direct-vent appliances, penetrate outside walls of buildings, the annular spaces around such penetrations shall be permanently sealed using approvedmaterials to prevent entry of combustion products into the building.

SECTION 504 (IFGS)

SIZING OF CATEGORY I APPLIANCE

VENTING SYSTEMS

504.1 Definitions.

The following definitions apply to the tables in this section.

APPLIANCE CATEGORIZED VENT DIAMETER/AREA. The minimum vent area/diameter permissible for Category I appliances to maintain a nonpositive vent static pressure when tested in accordance with nationally recognized standards.

FAN-ASSISTED COMBUSTION SYSTEM. An appliance equipped with an integral mechanical means to either draw or force products of combustion through the combustion chamber or heat exchanger.

FAN Min. The minimum input rating of a Category I fan-assisted appliance attached to a vent or connector.

FAN Max. The maximum input rating of a Category I fan-assisted appliance attached to a vent or connector.

NAT Max. The maximum input rating of a Category I draft-hood-equipped appliance attached to a vent or connector.

FAN + FAN. The maximum combined appliance input rating of two or more Category I fan-assisted appliances attached to the common vent.

FAN + NAT. The maximum combined appliance input rating of one or more Category I fan-assisted appliances and one or more Category I draft-hood-equipped appliances attached to the common vent.

NA. Vent configuration is not allowed due to potential for condensate formation or pressurization of the venting system, or not applicable due to physical or geometric restraints.

NAT + NAT. The maximum combined appliance input rating of two or more Category I draft-hood-equipped appliances attached to the common vent.

504.2 Application of single-appliance vent Tables 504.2(1) through 504.2(6).

The application of Tables 504.2(1) through 504.2(6) shall be subject to the requirements of Sections 504.2.1 through 504.2.17.

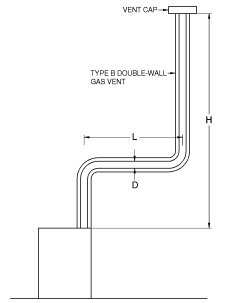

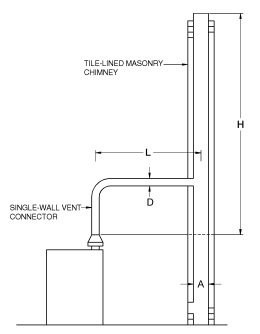

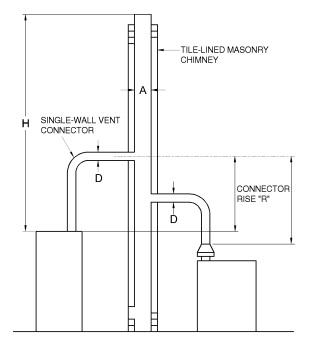

| For SI: 1 foot = 304.8 mm, 1 British thermal unit per hour = 0.2931 W. Table 504.2(1) is used when sizing Type B double-wall gas vent connected directly to the appliance. Note: The appliance may be either Category I draft hood equipped or fanassisted type. |

FIGURE B-1

TYPE B DOUBLE-WALL VENT SYSTEM SERVING A SINGLE

APPLIANCE WITH A TYPE B DOUBLE-WALL VENT

TABLE 504.2(1)

TYPE B DOUBLE-WALL GAS VENT

| Number of Appliances | Single |

| Appliance Type | Category I |

| Appliance Vent Connection | Connected directly to vent |

| HEIGHT (H) (feet) |

LATERAL (L) (feet) |

VENT DIAMETER—(D) inches | ||||||||||||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||||||||||||||||

| APPLIANCE INPUT RATING IN THOUSANDS OF BTU/H | ||||||||||||||||||||||

| FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | |||||||||

| Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | ||

| 6 | 0 | 0 | 78 | 46 | 0 | 152 | 86 | 0 | 251 | 141 | 0 | 375 | 205 | 0 | 524 | 285 | 0 | 698 | 370 | 0 | 897 | 470 |

| 2 | 13 | 51 | 36 | 18 | 97 | 67 | 27 | 157 | 105 | 32 | 232 | 157 | 44 | 321 | 217 | 53 | 425 | 285 | 63 | 543 | 370 | |

| 4 | 21 | 49 | 34 | 30 | 94 | 64 | 39 | 153 | 103 | 50 | 227 | 153 | 66 | 316 | 211 | 79 | 419 | 279 | 93 | 536 | 362 | |

| 6 | 25 | 46 | 32 | 36 | 91 | 61 | 47 | 149 | 100 | 59 | 223 | 149 | 78 | 310 | 205 | 93 | 413 | 273 | 110 | 530 | 354 | |

| 8 | 0 | 0 | 84 | 50 | 0 | 165 | 94 | 0 | 276 | 155 | 0 | 415 | 235 | 0 | 583 | 320 | 0 | 780 | 415 | 0 | 1,006 | 537 |

| 2 | 12 | 57 | 40 | 16 | 109 | 75 | 25 | 178 | 120 | 28 | 263 | 180 | 42 | 365 | 247 | 50 | 483 | 322 | 60 | 619 | 418 | |

| 5 | 23 | 53 | 38 | 32 | 103 | 71 | 42 | 171 | 115 | 53 | 255 | 173 | 70 | 356 | 237 | 83 | 473 | 313 | 99 | 607 | 407 | |

| 8 | 28 | 49 | 35 | 39 | 98 | 66 | 51 | 164 | 109 | 64 | 247 | 165 | 84 | 347 | 227 | 99 | 463 | 303 | 117 | 596 | 396 | |

| 10 | 0 | 0 | 88 | 53 | 0 | 175 | 100 | 0 | 295 | 166 | 0 | 447 | 255 | 0 | 631 | 345 | 0 | 847 | 450 | 0 | 1,096 | 585 |

| 2 | 12 | 61 | 42 | 17 | 118 | 81 | 23 | 194 | 129 | 26 | 289 | 195 | 40 | 402 | 273 | 48 | 533 | 355 | 57 | 684 | 457 | |

| 5 | 23 | 57 | 40 | 32 | 113 | 77 | 41 | 187 | 124 | 52 | 280 | 188 | 68 | 392 | 263 | 81 | 522 | 346 | 95 | 671 | 446 | |

| 10 | 30 | 51 | 36 | 41 | 104 | 70 | 54 | 176 | 115 | 67 | 267 | 175 | 88 | 376 | 245 | 104 | 504 | 330 | 122 | 651 | 427 | |

| 15 | 0 | 0 | 94 | 58 | 0 | 191 | 112 | 0 | 327 | 187 | 0 | 502 | 285 | 0 | 716 | 390 | 0 | 970 | 525 | 0 | 1,263 | 682 |

| 2 | 11 | 69 | 48 | 15 | 136 | 93 | 20 | 226 | 150 | 22 | 339 | 225 | 38 | 475 | 316 | 45 | 633 | 414 | 53 | 815 | 544 | |

| 5 | 22 | 65 | 45 | 30 | 130 | 87 | 39 | 219 | 142 | 49 | 330 | 217 | 64 | 463 | 300 | 76 | 620 | 403 | 90 | 800 | 529 | |

| 10 | 29 | 59 | 41 | 40 | 121 | 82 | 51 | 206 | 135 | 64 | 315 | 208 | 84 | 445 | 288 | 99 | 600 | 386 | 116 | 777 | 507 | |

| 15 | 35 | 53 | 37 | 48 | 112 | 76 | 61 | 195 | 128 | 76 | 301 | 198 | 98 | 429 | 275 | 115 | 580 | 373 | 134 | 755 | 491 | |

| 20 | 0 | 0 | 97 | 61 | 0 | 202 | 119 | 0 | 349 | 202 | 0 | 540 | 307 | 0 | 776 | 430 | 0 | 1,057 | 575 | 0 | 1,384 | 752 |

| 2 | 10 | 75 | 51 | 14 | 149 | 100 | 18 | 250 | 166 | 20 | 377 | 249 | 33 | 531 | 346 | 41 | 711 | 470 | 50 | 917 | 612 | |

| 5 | 21 | 71 | 48 | 29 | 143 | 96 | 38 | 242 | 160 | 47 | 367 | 241 | 62 | 519 | 337 | 73 | 697 | 460 | 86 | 902 | 599 | |

| 10 | 28 | 64 | 44 | 38 | 133 | 89 | 50 | 229 | 150 | 62 | 351 | 228 | 81 | 499 | 321 | 95 | 675 | 443 | 112 | 877 | 576 | |

| 15 | 34 | 58 | 40 | 46 | 124 | 84 | 59 | 217 | 142 | 73 | 337 | 217 | 94 | 481 | 308 | 111 | 654 | 427 | 129 | 853 | 557 | |

| 20 | 48 | 52 | 35 | 55 | 116 | 78 | 69 | 206 | 134 | 84 | 322 | 206 | 107 | 464 | 295 | 125 | 634 | 410 | 145 | 830 | 537 | |

(continued)

TABLE 504.2(1)—continued

TYPE B DOUBLE-WALL GAS VENT

| Number of Appliances | Single |

| Appliance Type | Category I |

| Appliance Vent Connection | Connected directly to vent |

| HEIGHT (H) (feet) |

LATERAL (L) (feet) |

VENT DIAMETER—(D) inches | ||||||||||||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||||||||||||||||

| APPLIANCE INPUT RATING IN THOUSANDS OF BTU/H | ||||||||||||||||||||||

| FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | |||||||||

| Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | ||

| 30 | 0 | 0 | 100 | 64 | 0 | 213 | 128 | 0 | 374 | 220 | 0 | 587 | 336 | 0 | 853 | 475 | 0 | 1,173 | 650 | 0 | 1,548 | 855 |

| 2 | 9 | 81 | 56 | 13 | 166 | 112 | 14 | 283 | 185 | 18 | 432 | 280 | 27 | 613 | 394 | 33 | 826 | 535 | 42 | 1,072 | 700 | |

| 5 | 21 | 77 | 54 | 28 | 160 | 108 | 36 | 275 | 176 | 45 | 421 | 273 | 58 | 600 | 385 | 69 | 811 | 524 | 82 | 1,055 | 688 | |

| 10 | 27 | 70 | 50 | 37 | 150 | 102 | 48 | 262 | 171 | 59 | 405 | 261 | 77 | 580 | 371 | 91 | 788 | 507 | 107 | 1,028 | 668 | |

| 15 | 33 | 64 | NA | 44 | 141 | 96 | 57 | 249 | 163 | 70 | 389 | 249 | 90 | 560 | 357 | 105 | 765 | 490 | 124 | 1,002 | 648 | |

| 20 | 56 | 58 | NA | 53 | 132 | 90 | 66 | 237 | 154 | 80 | 374 | 237 | 102 | 542 | 343 | 119 | 743 | 473 | 139 | 977 | 628 | |

| 30 | NA | NA | NA | 73 | 113 | NA | 88 | 214 | NA | 104 | 346 | 219 | 131 | 507 | 321 | 149 | 702 | 444 | 171 | 929 | 594 | |

| 50 | 0 | 0 | 101 | 67 | 0 | 216 | 134 | 0 | 397 | 232 | 0 | 633 | 363 | 0 | 932 | 518 | 0 | 1,297 | 708 | 0 | 1,730 | 952 |

| 2 | 8 | 86 | 61 | 11 | 183 | 122 | 14 | 320 | 206 | 15 | 497 | 314 | 22 | 715 | 445 | 26 | 975 | 615 | 33 | 1,276 | 813 | |

| 5 | 20 | 82 | NA | 27 | 177 | 119 | 35 | 312 | 200 | 43 | 487 | 308 | 55 | 702 | 438 | 65 | 960 | 605 | 77 | 1,259 | 798 | |

| 10 | 26 | 76 | NA | 35 | 168 | 114 | 45 | 299 | 190 | 56 | 471 | 298 | 73 | 681 | 426 | 86 | 935 | 589 | 101 | 1,230 | 773 | |

| 15 | 59 | 70 | NA | 42 | 158 | NA | 54 | 287 | 180 | 66 | 455 | 288 | 85 | 662 | 413 | 100 | 911 | 572 | 117 | 1,203 | 747 | |

| 20 | NA | NA | NA | 50 | 149 | NA | 63 | 275 | 169 | 76 | 440 | 278 | 97 | 642 | 401 | 113 | 888 | 556 | 131 | 1,176 | 722 | |

| 30 | NA | NA | NA | 69 | 131 | NA | 84 | 250 | NA | 99 | 410 | 259 | 123 | 605 | 376 | 141 | 844 | 522 | 161 | 1,125 | 670 | |

| 100 | 0 | NA | NA | NA | 0 | 218 | NA | 0 | 407 | NA | 0 | 665 | 400 | 0 | 997 | 560 | 0 | 1,411 | 770 | 0 | 1,908 | 1,040 |

| 2 | NA | NA | NA | 10 | 194 | NA | 12 | 354 | NA | 13 | 566 | 375 | 18 | 831 | 510 | 21 | 1,155 | 700 | 25 | 1,536 | 935 | |

| 5 | NA | NA | NA | 26 | 189 | NA | 33 | 347 | NA | 40 | 557 | 369 | 52 | 820 | 504 | 60 | 1,141 | 692 | 71 | 1,519 | 926 | |

| 10 | NA | NA | NA | 33 | 182 | NA | 43 | 335 | NA | 53 | 542 | 361 | 68 | 801 | 493 | 80 | 1,118 | 679 | 94 | 1,492 | 910 | |

| 15 | NA | NA | NA | 40 | 174 | NA | 50 | 321 | NA | 62 | 528 | 353 | 80 | 782 | 482 | 93 | 1,095 | 666 | 109 | 1,465 | 895 | |

| 20 | NA | NA | NA | 47 | 166 | NA | 59 | 311 | NA | 71 | 513 | 344 | 90 | 763 | 471 | 105 | 1,073 | 653 | 122 | 1,438 | 880 | |

| 30 | NA | NA | NA | NA | NA | NA | 78 | 290 | NA | 92 | 483 | NA | 115 | 726 | 449 | 131 | 1,029 | 627 | 149 | 1,387 | 849 | |

| 50 | NA | NA | NA | NA | NA | NA | NA | NA | NA | 147 | 428 | NA | 180 | 651 | 405 | 197 | 944 | 575 | 217 | 1,288 | 787 | |

(continued)

TABLE 504.2(1)—continued

TYPE B DOUBLE-WALL GAS VENT

| Number of Appliances | Single |

| Appliance Type | Category I |

| Appliance Vent Connection | Connected directly to vent |

| HEIGHT (H) (feet) |

LATERAL (L) (feet) |

VENT DIAMETER—(D) inches | |||||||||||||||||||||||

| 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | ||||||||||||||||||

| APPLIANCE INPUT RATING IN THOUSANDS OF BTU/H | |||||||||||||||||||||||||

| FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | ||||||||||

| Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | ||

| 6 | 0 | 0 | 1,121 | 570 | 0 | 1,645 | 850 | 0 | 2,267 | 1,170 | 0 | 2,983 | 1,530 | 0 | 3,802 | 1,960 | 0 | 4,721 | 2,430 | 0 | 5,737 | 2,950 | 0 | 6,853 | 3,520 |

| 2 | 75 | 675 | 455 | 103 | 982 | 650 | 138 | 1,346 | 890 | 178 | 1,769 | 1,170 | 225 | 2,250 | 1,480 | 296 | 2,782 | 1,850 | 360 | 3,377 | 2,220 | 426 | 4,030 | 2,670 | |

| 4 | 110 | 668 | 445 | 147 | 975 | 640 | 191 | 1,338 | 880 | 242 | 1,761 | 1,160 | 300 | 2,242 | 1,475 | 390 | 2,774 | 1,835 | 469 | 3,370 | 2,215 | 555 | 4,023 | 2,660 | |

| 6 | 128 | 661 | 435 | 171 | 967 | 630 | 219 | 1,330 | 870 | 276 | 1,753 | 1,150 | 341 | 2,235 | 1,470 | 437 | 2,767 | 1,820 | 523 | 3,363 | 2,210 | 618 | 4,017 | 2,650 | |

| 8 | 0 | 0 | 1,261 | 660 | 0 | 1,858 | 970 | 0 | 2,571 | 1,320 | 0 | 3,399 | 1,740 | 0 | 4,333 | 2,220 | 0 | 5,387 | 2,750 | 0 | 6,555 | 3,360 | 0 | 7,838 | 4,010 |

| 2 | 71 | 770 | 515 | 98 | 1,124 | 745 | 130 | 1,543 | 1,020 | 168 | 2,030 | 1,340 | 212 | 2,584 | 1,700 | 278 | 3,196 | 2,110 | 336 | 3,882 | 2,560 | 401 | 4,634 | 3,050 | |

| 5 | 115 | 758 | 503 | 154 | 1,110 | 733 | 199 | 1,528 | 1,010 | 251 | 2,013 | 1,330 | 311 | 2,563 | 1,685 | 398 | 3,180 | 2,090 | 476 | 3,863 | 2,545 | 562 | 4,612 | 3,040 | |

| 8 | 137 | 746 | 490 | 180 | 1,097 | 720 | 231 | 1,514 | 1,000 | 289 | 2,000 | 1,320 | 354 | 2,552 | 1,670 | 450 | 3,163 | 2,070 | 537 | 3,850 | 2,530 | 630 | 4,602 | 3,030 | |

| 10 | 0 | 0 | 1,377 | 720 | 0 | 2,036 | 1,060 | 0 | 2,825 | 1,450 | 0 | 3,742 | 1,925 | 0 | 4,782 | 2,450 | 0 | 5,955 | 3,050 | 0 | 7,254 | 3,710 | 0 | 8,682 | 4,450 |

| 2 | 68 | 852 | 560 | 93 | 1,244 | 850 | 124 | 1,713 | 1,130 | 161 | 2,256 | 1,480 | 202 | 2,868 | 1,890 | 264 | 3,556 | 2,340 | 319 | 4,322 | 2,840 | 378 | 5,153 | 3,390 | |

| 5 | 112 | 839 | 547 | 149 | 1,229 | 829 | 192 | 1,696 | 1,105 | 243 | 2,238 | 1,461 | 300 | 2,849 | 1,871 | 382 | 3,536 | 2,318 | 458 | 4,301 | 2,818 | 540 | 5,132 | 3,371 | |

| 10 | 142 | 817 | 525 | 187 | 1,204 | 795 | 238 | 1,669 | 1,080 | 298 | 2,209 | 1,430 | 364 | 2,818 | 1,840 | 459 | 3,504 | 2,280 | 546 | 4,268 | 2,780 | 641 | 5,099 | 3,340 | |

| 15 | 0 | 0 | 1,596 | 840 | 0 | 2,380 | 1,240 | 0 | 3,323 | 1,720 | 0 | 4,423 | 2,270 | 0 | 5,678 | 2,900 | 0 | 7,099 | 3,620 | 0 | 8,665 | 4,410 | 0 | 10,393 | 5,300 |

| 2 | 63 | 1,019 | 675 | 86 | 1,495 | 985 | 114 | 2,062 | 1,350 | 147 | 2,719 | 1,770 | 186 | 3,467 | 2,260 | 239 | 4,304 | 2,800 | 290 | 5,232 | 3,410 | 346 | 6,251 | 4,080 | |

| 5 | 105 | 1,003 | 660 | 140 | 1,476 | 967 | 182 | 2,041 | 1,327 | 229 | 2,696 | 1,748 | 283 | 3,442 | 2,235 | 355 | 4,278 | 2,777 | 426 | 5,204 | 3,385 | 501 | 6,222 | 4,057 | |

| 10 | 135 | 977 | 635 | 177 | 1,446 | 936 | 227 | 2,009 | 1,289 | 283 | 2,659 | 1,712 | 346 | 3,402 | 2,193 | 432 | 4,234 | 2,739 | 510 | 5,159 | 3,343 | 599 | 6,175 | 4,019 | |

| 15 | 155 | 953 | 610 | 202 | 1,418 | 905 | 257 | 1,976 | 1,250 | 318 | 2,623 | 1,675 | 385 | 3,363 | 2,150 | 479 | 4,192 | 2,700 | 564 | 5,115 | 3,300 | 665 | 6,129 | 3,980 | |

| 20 | 0 | 0 | 1,756 | 930 | 0 | 2,637 | 1,350 | 0 | 3,701 | 1,900 | 0 | 4,948 | 2,520 | 0 | 6,376 | 3,250 | 0 | 7,988 | 4,060 | 0 | 9,785 | 4,980 | 0 | 11,753 | 6,000 |

| 2 | 59 | 1,150 | 755 | 81 | 1,694 | 1,100 | 107 | 2,343 | 1,520 | 139 | 3,097 | 2,000 | 175 | 3,955 | 2,570 | 220 | 4,916 | 3,200 | 269 | 5,983 | 3,910 | 321 | 7,154 | 4,700 | |

| 5 | 101 | 1,133 | 738 | 135 | 1,674 | 1,079 | 174 | 2,320 | 1,498 | 219 | 3,071 | 1,978 | 270 | 3,926 | 2,544 | 337 | 4,885 | 3,174 | 403 | 5,950 | 3,880 | 475 | 7,119 | 4,662 | |

| 10 | 130 | 1,105 | 710 | 172 | 1,641 | 1,045 | 220 | 2,282 | 1,460 | 273 | 3,029 | 1,940 | 334 | 3,880 | 2,500 | 413 | 4,835 | 3,130 | 489 | 5,896 | 3,830 | 573 | 7,063 | 4,600 | |

| 15 | 150 | 1,078 | 688 | 195 | 1,609 | 1,018 | 248 | 2,245 | 1,425 | 306 | 2,988 | 1,910 | 372 | 3,835 | 2,465 | 459 | 4,786 | 3,090 | 541 | 5,844 | 3,795 | 631 | 7,007 | 4,575 | |

| 20 | 167 | 1,052 | 665 | 217 | 1,578 | 990 | 273 | 2,210 | 1,390 | 335 | 2,948 | 1,880 | 404 | 3,791 | 2,430 | 495 | 4,737 | 3,050 | 585 | 5,792 | 3,760 | 689 | 6,953 | 4,550 | |

(continued)

TABLE 504.2(1)—continued

TYPE B DOUBLE-WALL GAS VENT

| Number of Appliances | Single |

| Appliance Type | Category I |

| Appliance Vent Connection | Connected directly to vent |

| HEIGHT (H) (feet) |

LATERAL (L) (feet) |

VENT DIAMETER—(D) inches | |||||||||||||||||||||||

| 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | ||||||||||||||||||

| APPLIANCE INPUT RATING IN THOUSANDS OF BTU/H | |||||||||||||||||||||||||

| FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | ||||||||||

| Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | ||

| 30 | 0 | 0 | 1,977 | 1,060 | 0 | 3,004 | 1,550 | 0 | 4,252 | 2,170 | 0 | 5,725 | 2,920 | 0 | 7,420 | 3,770 | 0 | 9,341 | 4,750 | 0 | 11,483 | 5,850 | 0 | 13,848 | 7,060 |

| 2 | 54 | 1,351 | 865 | 74 | 2,004 | 1,310 | 98 | 2,786 | 1,800 | 127 | 3,696 | 2,380 | 159 | 4,734 | 3,050 | 199 | 5,900 | 3,810 | 241 | 7,194 | 4,650 | 285 | 8,617 | 5,600 | |

| 5 | 96 | 1,332 | 851 | 127 | 1,981 | 1,289 | 164 | 2,759 | 1,775 | 206 | 3,666 | 2,350 | 252 | 4,701 | 3,020 | 312 | 5,863 | 3,783 | 373 | 7,155 | 4,622 | 439 | 8,574 | 5,552 | |

| 10 | 125 | 1,301 | 829 | 164 | 1,944 | 1,254 | 209 | 2,716 | 1,733 | 259 | 3,617 | 2,300 | 316 | 4,647 | 2,970 | 386 | 5,803 | 3,739 | 456 | 7,090 | 4,574 | 535 | 8,505 | 5,471 | |

| 15 | 143 | 1,272 | 807 | 187 | 1,908 | 1,220 | 237 | 2,674 | 1,692 | 292 | 3,570 | 2,250 | 354 | 4,594 | 2,920 | 431 | 5,744 | 3,695 | 507 | 7,026 | 4,527 | 590 | 8,437 | 5,391 | |

| 20 | 160 | 1,243 | 784 | 207 | 1,873 | 1,185 | 260 | 2,633 | 1,650 | 319 | 3,523 | 2,200 | 384 | 4,542 | 2,870 | 467 | 5,686 | 3,650 | 548 | 6,964 | 4,480 | 639 | 8,370 | 5,310 | |

| 30 | 195 | 1,189 | 745 | 246 | 1,807 | 1,130 | 305 | 2,555 | 1,585 | 369 | 3,433 | 2,130 | 440 | 4,442 | 2,785 | 540 | 5,574 | 3,565 | 635 | 6,842 | 4,375 | 739 | 8,239 | 5,225 | |

| 50 | 0 | 0 | 2,231 | 1,195 | 0 | 3,441 | 1,825 | 0 | 4,934 | 2,550 | 0 | 6,711 | 3,440 | 0 | 8,774 | 4,460 | 0 | 11,129 | 5,635 | 0 | 13,767 | 6,940 | 0 | 16,694 | 8,430 |

| 2 | 41 | 1,620 | 1,010 | 66 | 2,431 | 1,513 | 86 | 3,409 | 2,125 | 113 | 4,554 | 2,840 | 141 | 5,864 | 3,670 | 171 | 7,339 | 4,630 | 209 | 8,980 | 5,695 | 251 | 10,788 | 6,860 | |

| 5 | 90 | 1,600 | 996 | 118 | 2,406 | 1,495 | 151 | 3,380 | 2,102 | 191 | 4,520 | 2,813 | 234 | 5,826 | 3,639 | 283 | 7,295 | 4,597 | 336 | 8,933 | 5,654 | 394 | 10,737 | 6,818 | |

| 10 | 118 | 1,567 | 972 | 154 | 2,366 | 1,466 | 196 | 3,332 | 2,064 | 243 | 4,464 | 2,767 | 295 | 5,763 | 3,585 | 355 | 7,224 | 4,542 | 419 | 8,855 | 5,585 | 491 | 10,652 | 6,749 | |

| 15 | 136 | 1,536 | 948 | 177 | 2,327 | 1,437 | 222 | 3,285 | 2,026 | 274 | 4,409 | 2,721 | 330 | 5,701 | 3,534 | 396 | 7,155 | 4,511 | 465 | 8,779 | 5,546 | 542 | 10,570 | 6,710 | |

| 20 | 151 | 1,505 | 924 | 195 | 2,288 | 1,408 | 244 | 3,239 | 1,987 | 300 | 4,356 | 2,675 | 361 | 5,641 | 3,481 | 433 | 7,086 | 4,479 | 506 | 8,704 | 5,506 | 586 | 10,488 | 6,670 | |

| 30 | 183 | 1,446 | 876 | 232 | 2,214 | 1,349 | 287 | 3,150 | 1,910 | 347 | 4,253 | 2,631 | 412 | 5,523 | 3,431 | 494 | 6,953 | 4,421 | 577 | 8,557 | 5,444 | 672 | 10,328 | 6,603 | |

| 100 | 0 | 0 | 2,491 | 1,310 | 0 | 3,925 | 2,050 | 0 | 5,729 | 2,950 | 0 | 7,914 | 4,050 | 0 | 10,485 | 5,300 | 0 | 13,454 | 6,700 | 0 | 16,817 | 8,600 | 0 | 20,578 | 10,300 |

| 2 | 30 | 1,975 | 1,170 | 44 | 3,027 | 1,820 | 72 | 4,313 | 2,550 | 95 | 5,834 | 3,500 | 120 | 7,591 | 4,600 | 138 | 9,577 | 5,800 | 169 | 11,803 | 7,200 | 204 | 14,264 | 8,800 | |

| 5 | 82 | 1,955 | 1,159 | 107 | 3,002 | 1,803 | 136 | 4,282 | 2,531 | 172 | 5,797 | 3,475 | 208 | 7,548 | 4,566 | 245 | 9,528 | 5,769 | 293 | 11,748 | 7,162 | 341 | 14,204 | 8,756 | |

| 10 | 108 | 1,923 | 1,142 | 142 | 2,961 | 1,775 | 180 | 4,231 | 2,500 | 223 | 5,737 | 3,434 | 268 | 7,478 | 4,509 | 318 | 9,447 | 5,717 | 374 | 11,658 | 7,100 | 436 | 14,105 | 8,683 | |

| 15 | 126 | 1,892 | 1,124 | 163 | 2,920 | 1,747 | 206 | 4,182 | 2,469 | 252 | 5,678 | 3,392 | 304 | 7,409 | 4,451 | 358 | 9,367 | 5,665 | 418 | 11,569 | 7,037 | 487 | 14,007 | 8,610 | |

| 20 | 141 | 1,861 | 1,107 | 181 | 2,880 | 1,719 | 226 | 4,133 | 2,438 | 277 | 5,619 | 3,351 | 330 | 7,341 | 4,394 | 387 | 9,289 | 5,613 | 452 | 11,482 | 6,975 | 523 | 13,910 | 8,537 | |

| 30 | 170 | 1,802 | 1,071 | 215 | 2,803 | 1,663 | 265 | 4,037 | 2,375 | 319 | 5,505 | 3,267 | 378 | 7,209 | 4,279 | 446 | 9,136 | 5,509 | 514 | 11,310 | 6,850 | 592 | 13,720 | 8,391 | |

| 50 | 241 | 1,688 | 1,000 | 292 | 2,657 | 1,550 | 350 | 3,856 | 2,250 | 415 | 5,289 | 3,100 | 486 | 6,956 | 4,050 | 572 | 8,841 | 5,300 | 659 | 10,979 | 6,600 | 752 | 13,354 | 8,100 | |

| For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 British thermal unit per hour = 0.2931 W. |

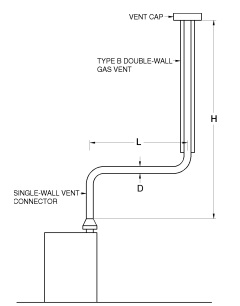

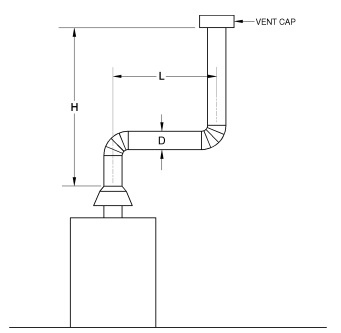

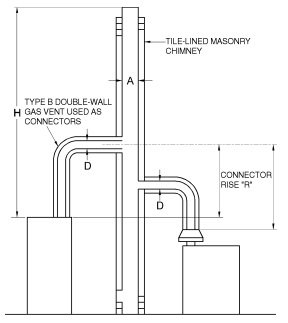

| For SI: 1 foot = 304.8 mm, 1 British thermal unit per hour = 0.2931 W. Table 504.2(2) is used when sizing a single-wall metal vent connector attached to a Type B double-wall gas vent. Note: The appliance may be either Category I draft hood equipped or fanassisted type. |

FIGURE B-2

TYPE B DOUBLE-WALL VENT SYSTEM SERVING A SINGLE

APPLIANCE WITH A SINGLE-WALL METAL VENT CONNECTOR

TABLE 504.2(2)

TYPE B DOUBLE-WALL GAS VENT

| Number of Appliances | Single |

| Appliance Type | Category I |

| Appliance Vent Connection | Single-wall metal connector |

| HEIGHT (H) (feet) |

LATERAL (L) (feet) |

VENT DIAMETER—(D) Inches | ||||||||||||||||||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | ||||||||||||||||||||

| APPLIANCE INPUT RATING IN THOUSANDS OF BTU/H | ||||||||||||||||||||||||||||

| FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | FAN | NAT | |||||||||||

| Mln | Max | Max | Mln | Max | Max | Mln | Max | Max | Mln | Max | Max | Mln | Max | Max | Mln | Max | Max | Mln | Max | Max | Mln | Max | Max | Mln | Max | Max | ||

| 6 | 0 | 38 | 77 | 45 | 59 | 151 | 85 | 85 | 249 | 140 | 126 | 373 | 204 | 165 | 522 | 284 | 211 | 695 | 369 | 267 | 894 | 469 | 371 | 1,118 | 569 | 537 | 1.639 | 849 |

| 2 | 39 | 51 | 36 | 60 | 96 | 66 | 85 | 156 | 104 | 123 | 231 | 156 | 159 | 320 | 213 | 201 | 423 | 284 | 251 | 541 | 368 | 347 | 673 | 453 | 498 | 979 | 648 | |

| 4 | NA | NA | 33 | 74 | 92 | 63 | 102 | 152 | 102 | 146 | 225 | 152 | 187 | 313 | 208 | 237 | 416 | 277 | 295 | 533 | 360 | 409 | 664 | 443 | 584 | 971 | 638 | |

| 6 | NA | NA | 31 | 83 | 89 | 60 | 114 | 147 | 99 | 163 | 220 | 148 | 207 | 307 | 203 | 263 | 409 | 271 | 327 | 526 | 352 | 449 | 656 | 433 | 638 | 962 | 627 | |

| 8 | 0 | 37 | 83 | 50 | 58 | 164 | 93 | 83 | 273 | 154 | 123 | 412 | 234 | 161 | 580 | 319 | 206 | 777 | 414 | 258 | 1,002 | 536 | 360 | 1,257 | 658 | 521 | 1,852 | 967 |

| 2 | 39 | 56 | 39 | 59 | 108 | 75 | 83 | 176 | 119 | 121 | 261 | 179 | 155 | 363 | 246 | 197 | 482 | 321 | 246 | 617 | 417 | 339 | 768 | 513 | 486 | 1,120 | 743 | |

| 5 | NA | NA | 37 | 77 | 102 | 69 | 107 | 168 | 114 | 151 | 252 | 171 | 193 | 352 | 235 | 245 | 470 | 311 | 305 | 604 | 404 | 418 | 754 | 500 | 598 | 1,104 | 730 | |

| 8 | NA | NA | 33 | 90 | 95 | 64 | 122 | 161 | 107 | 175 | 243 | 163 | 223 | 342 | 225 | 280 | 458 | 300 | 344 | 591 | 392 | 470 | 740 | 486 | 665 | 1.089 | 715 | |

| 10 | 0 | 37 | 87 | 53 | 57 | 174 | 99 | 82 | 293 | 165 | 120 | 444 | 254 | 158 | 628 | 344 | 202 | 844 | 449 | 253 | 1,093 | 584 | 351 | 1,373 | 718 | 507 | 2,031 | 1,057 |